When purchasing bottling equipment, today’s dairy and beverage manufacturers need solutions that are flexible, simple to use, and cost and space efficient. These characteristics are especially important for low-volume production scenarios (i.e., 8,000 bottles-per-hour of fewer) when labor, floorspace and capital equipment budgets tend to be in short supply. For this reason, Synerlink has developed the CombiBlow, an all-in-one bottling solution for blowing, filling, and capping PET bottles.

In this post, you will learn some of the top advantages that make CombiBlow an ideal solution for low-volume dairy and beverage products in bottles.

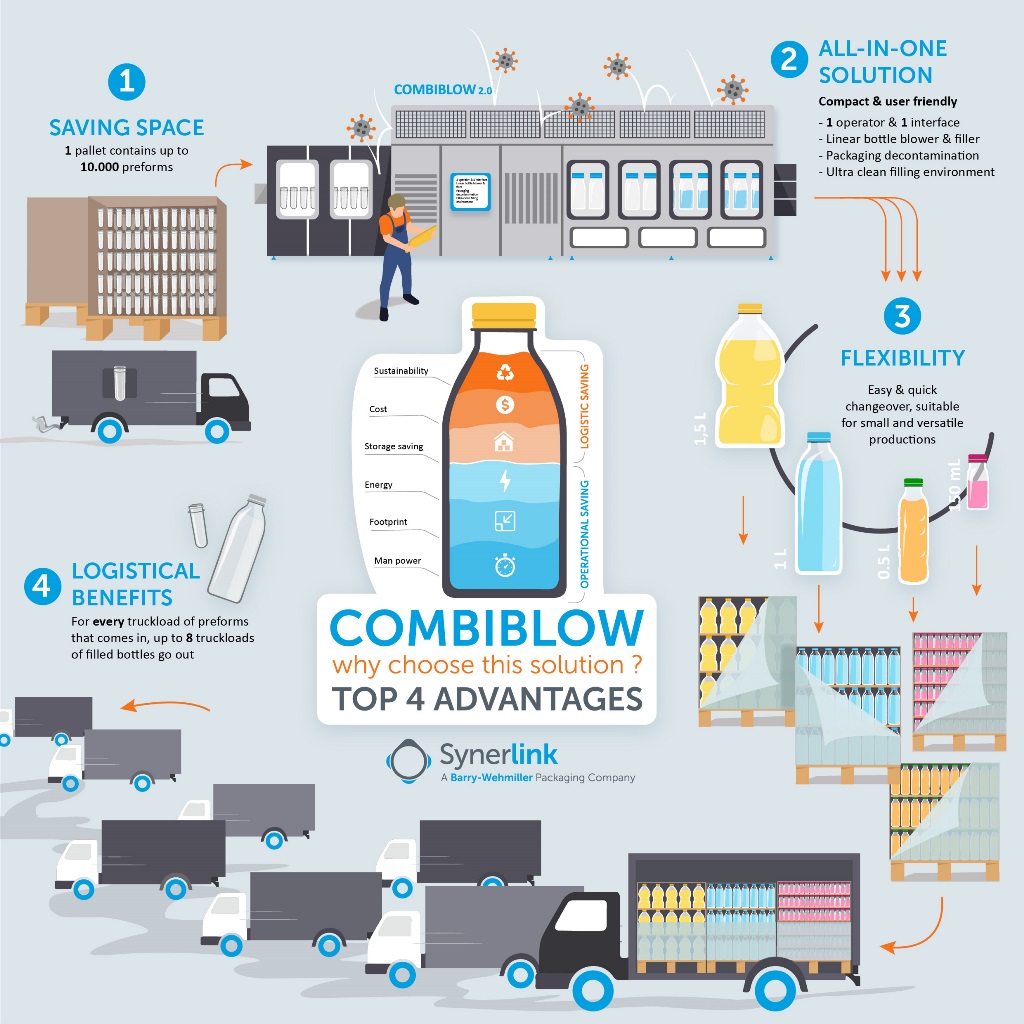

Top 4 Advantages of Synerlink’s CombiBlow 2.0 Solution

SAVING SPACE WITH PREFORMS

Storing empty bottles is a logistical challenge for dairy and beverage processors because they eat up space and drive higher storage expenses as a result. Preforms, on the other hand, use 10x less space than formed bottles. In fact, a single

pallet can hold up to 10,000 preforms. For this reason, we’ve designed the CombiBlow 2.0 solution to blow preforms, allowing you to save on space and expenses before you even start the production process.

ALL-IN-ONE SOLUTION REDUCES TROUBLESHOOTING

Manufacturers who purchase separate machines for blowing, filling, and capping bottles tend to spend more time troubleshooting because different OEMs use different interfaces. However, the CombiBlow 2.0 complete line solution can be operated

by a single person via Synerlink’s Efidrive HMI. This ultra clean filling solution has been tested and refined to guarantee smoother operation.

FLEXIBILITY ENSURES VERSATILE PRODUCTION

The CombiBlow 2.0 solution can accommodate a wide range of formats from 150ml to 1.5l bottles with 2 necks options. This complete line solution also includes quick and easy changeovers, allowing dairy and beverage processors to bottle a wide

range of products on the same machine including dairy products, fruit juices, soups, smoothies, nutritional drinks, coffees, teas, fermented products, and many more.

LOGISTICAL BENEFITS

In addition to reduced troubleshooting, the all-in-one solution is compact and occupies a smaller footprint in your plant. Additionally, while preforms do not occupy a large amount of space in your facility, they allow dairy and beverage processors

to have impressive outputs. For every preform truckload that comes in, up to eight filled bottle truckload go out.

Interesting in learning more about Synerlink’s CombiBlow 2.0? Contact us.